February 6th, 2015Success Stories Product Information

Industrial Measurement Systems

Precision Temperature Control

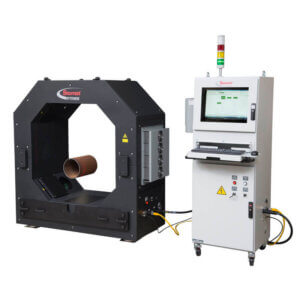

Starrett-Bytewise manufactures laser-based, non-contact, dimensional measurement systems that are employed on the factory floor for quality monitoring, process control and inspection. Starrett-Bytewise is comprised of industry-leading experts in laser sensor development, metrology and software development. This expertise coupled with product dedication and experience makes their measurement systems the most accurate, reliable and easy to use in the rubber extrusion, plastic extrusion, WPC lumber, tire building and airfoil industries.

To create these measurement systems, Starrett-Bytewise uses sheet of light triangulation sensors to measure a wide variety of materials including tires, oil and gas pipe, wire and others. One of the most common problems that can affect the accuracy of laser sensors is temperature. Both temperature drift of the electronics and expansion and contraction of mechanical components can change the sensor gap. To avoid this problem, Starrett-Bytewise needed a temperature control solution that was equally as accurate as the products they deliver.

ThermoTEC™ 151 Series – 2500 BTU Thermoelectric Air Conditioner – Rear View, Right Side

ThermoTEC™ 151 Series – 2500 BTU Thermoelectric Air Conditioner – Rear View, Right SideStarrett-Bytewise searched for a solution online and found EIC Solutions. Experienced, knowledgeable EIC sales engineers worked with the Starrett-Bytewise team to find the best cooling options for their measurement systems.

EIC recommended using ThermoTEC™ 145 Series and ThermoTEC™ 151 Series thermoelectric coolers with integral heaters for devices that are subject to significant temperature changes. These rugged and dependable thermoelectric devices are designed to protect electronic equipment in the harshest of environments.

Because accuracy is just as important as cooling in their measurement systems, EIC recommended using the thermoelectric heating/cooling units in association with a digital temperature controller for a precision temperature control solution.

The EIC systems have a great industrial design with optional remote control capability. This smart design allowed Starrett-Bytewise to integrate the PID controller to have greater control of the temperature and reduce the maintenance associated with the cooling system.

EIC’s extensive thermoelectric cooling experience and quality products helped to improve the precision specifications in these industry-leading measuring systems. By using EIC’s solutions coupled with proper chassis insulation, Starrett-Bytewise maintains internal temperatures of +/- 1 degree Celsius in their products, eliminating any inaccuracies associated with thermal drift.